Grounding Blocks

Grounding Blocks

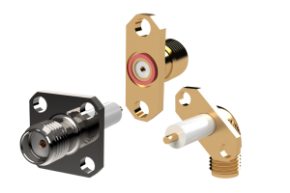

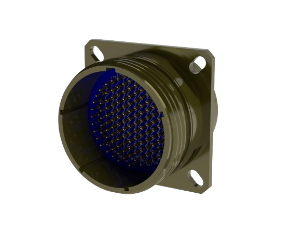

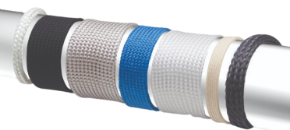

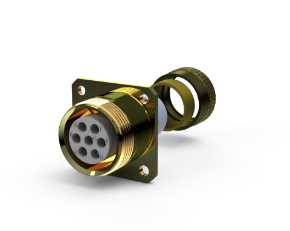

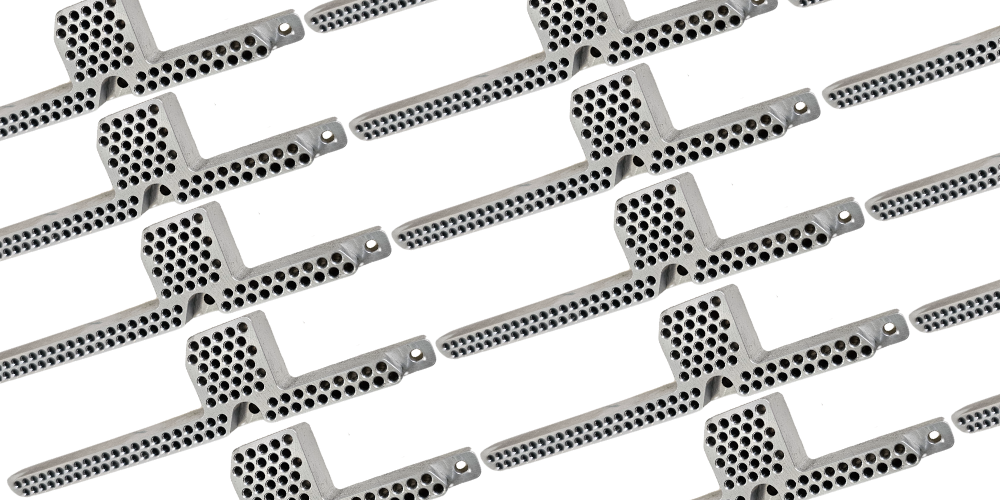

Amphenol CDI Grounding Blocks are essential components for protecting RF systems from electrical surges and ensuring reliable signal performance. Designed to provide a low-resistance path to ground, these blocks help prevent damage caused by static discharge, lightning strikes, and power surges.

Engineered for aerospace, military, space, and industrial applications, Amphenol CDI grounding blocks are built with high-quality materials to ensure long-term durability and corrosion resistance. Whether used in RF, coaxial, or broadband systems, they enhance system stability and comply with industry grounding and shielding standards.

Key Features:

✔ Provides a secure ground connection for RF systems

✔ Minimizes electrical interference and signal degradation

✔ Durable construction for long-lasting performance

✔ Available in multiple configurations to suit various applications

✔ Tested for performance, reliability, and environmental resistance

Ensure the safety and efficiency of your RF systems with high-performance grounding blocks from Amphenol CDI, designed for demanding environments.