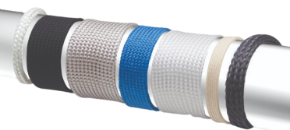

At Amphenol CDI, we deliver precision-engineered overbraiding solutions to enhance the performance, durability, and aesthetics of your cable harnesses. With state-of-the-art cable braiding technology and multiple 8 to 96 Carriage New England Butt Braiders in our California manufacturing facility, we provide high-quality, custom cable overbraiding for even the most complex interconnectivity projects.

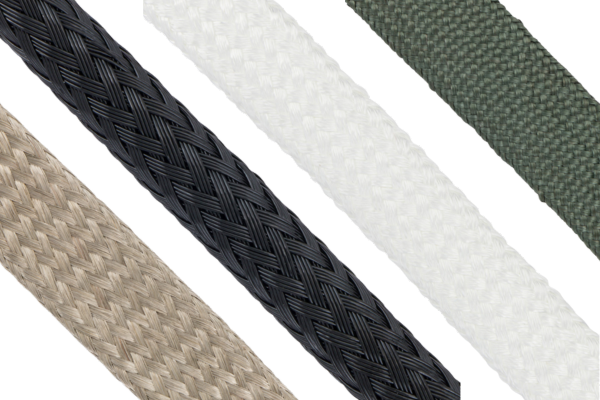

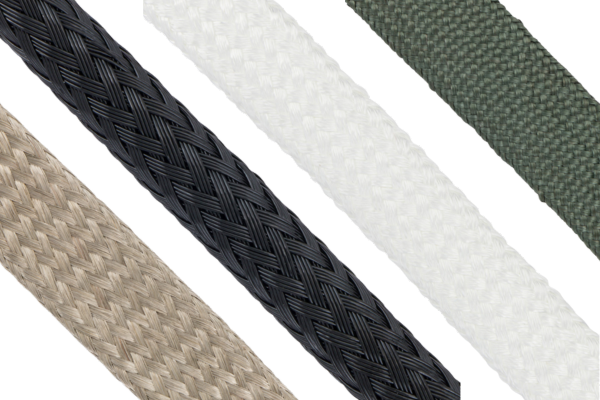

Our overbraiding capabilities extend across aerospace, automotive, marine, and industrial electrical applications, offering solutions for insulation, abrasion resistance, burst strength, and aesthetic enhancement. We can apply multi-sweater braiding over harnesses ranging from single-branch to multi-branched configurations, using materials such as synthetic fibers and metallic wire reinforcements.

Key Features & Capabilities:

✔ Custom Overbraiding – Enhances cable durability, shielding, and mechanical strength

✔ Material Versatility – Options include synthetic fibers, monofilament sleeving, and metallic wire reinforcements

✔ Precision Engineering – Overbraiding directly onto wires or cables for a seamless finish

✔ Quick-Turn Manufacturing – Expedited production with turnaround times as fast as 24-48 hours

✔ Trusted by Industry Leaders – Approved by major aerospace and defense contractors, including Boeing, Honeywell, GE, Lockheed Martin, and Northrop Grumman

Using your samples or prints, we provide prompt estimates and cost-effective solutions tailored to your specific cable protection needs. Our advanced high-speed equipment ensures minimal waste and maximum efficiency, keeping your production timelines on track.

From ruggedized cable assemblies to specialized strength-to-weight ratio requirements, Amphenol CDI’s custom overbraiding solutions provide the ultimate performance and protection for your mission-critical applications.