D-Sub & Micro D Connectors

D-Sub & Micro-D Connectors

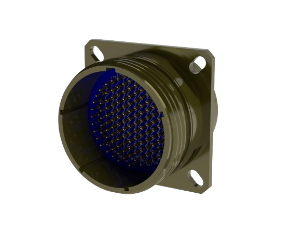

Amphenol CDI D-Sub & Micro-D filter connectors meet all the requirements of MIL-PRF-24308 and MIL-PRF-83513 while providing filtering in accordance with the attenuation curves noted herein. MIL-PRF-24308 connectors (Standard density and Hi-density) and MIL-PRF-83513 are manufactured in all layouts offering maximum contact density in a minimum of space.

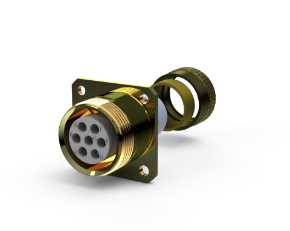

Both series of connectors are offered with the standard variations in mounting hardware, standard straight or right angle contacts and PCB, solder cup, and crimp termination.

Performance Benefits / Certification

- Planar design

- Machined shells

- Ferrite immobilization

- Space qualified

- Can incorporate filtering plus Transient Voltage Suppression

- Can meet DO-160 lightning requirements

Design Considerations

| Rectangular | Mating End Contacts | Filter Types* | Electrical | Environmental | Mounting Hardware | Contact Terminations |

|---|---|---|---|---|---|---|

| MIL-DTL-24308 | Pin | C | Feed Thru Contacts | Thermal Cycle | Clinch Nut | PC Tails |

| MIL-DTL-83513 | Socket | Pi | Ground Contacts | Thermal Shock | Helicoil | Solder Cup |

| C-L/L-C | DWV min ____ VDC | Burn-in | Jack Posts | Crimp | ||

| T | Immersion | Wire Wrap | ||||

| Capacitance | ||||||

| Attenuation |

* Maximum or Mixed Capacitance Requirement? ____pF

Mechanical & Environmental Performance

| Test Description | Procedure |

|---|---|

| Temperature Cycling | EIA-364-32 Condition I |

| Durability | 500 Matings at a rate of 200 ± 100 cycles per hour |

| Shock | EIA-364-27, 3 Axis |

| Vibration | EIA-364-28 Condition IV |

| Fluid Immersion | EIA-364-10 Test Fluids (a) and (d) |

| Salt Spray | EIA-364-26 Condition B |

| Humidity | EIA-364-31 Method IV |